Like many of you, Texas Torque struggled with the decision about which motors to purchase for this season. We liked the power and neatness of the Falcon 500 but were concerned about the extra cost. That was before the price jumped to to $219.99.

On the other hand, the NEO plus a SPARK MAX was significantly cheaper at $48 for the motor and $90 for the controller. If a NEO or SPARK MAX failed, you could replace the individual component. With a Falcon 500, failure meant replacing the entire device, motor and controller.

I really like the simplicity and clean look of the Falcon 500 package. While failure was expensive, it was also easy to replace one motor with a built-in controller. When the NEO was back in stock last November, before the Falcon 500 was available, we decided to purchase the NEO motors and SPARK MAX controllers for the upcoming season.

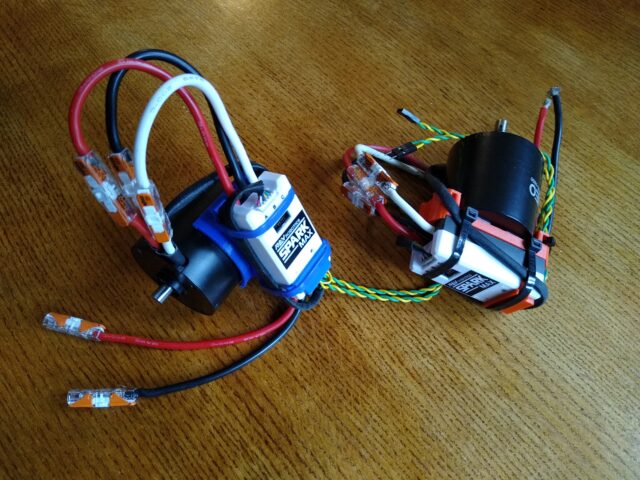

I found some ideas online for mounts to hold a SPARK MAX controller on the side of a NEO motor. I decided to design one for Texas Torque. A few revisions later, with input from our mechanical and electrical teams, I settled on two versions, one to mount to the top of the NEO and the other a side mount. I decided they should be called MAX Hats. We call the combination of the motor, controller, and MAX Hat a NEO MAX.

We have made the most use of the side mounted version but I think we will see the other version get more use as the CAD team starts thinking of the NEO MAX as a part instead of just the NEO with a SPARK MAX mounted somewhere close by. As our Week 4 event approaches, we had our first failure of a MAX Hat. New versions will have a higher percentage infill. We used PLA but are also looking at alternatives with greater impact resistance. It looks like the edge of the MAX Hat was hitting something periodically, probably the Charge Station ramp.

The files for both version of the MAX Hat can be found in the MAX Hat folder on our Google Drive using the following link.

MAX Hat Folder

You will also find a small part called the CAN Clip, an add-on that helps hold the CAN BUS connector in place. There are SolidWorks, STEP, and STL versions of each file. We hope you find these useful and would love to get some feedback from users.